Turboguide FAQ

Turbo manifold

The turbo manifold is one of the most important components of the turbo kit. The turbocharger is mounted directly on the manifold so that the exhaust gases can drive the turbocharger. With us you have a wide range of finished cast manifolds. If you cannot find a manifold for your vehicle, we will be happy to supply you with our laser-cut exhaust manifold and turbocharger flange plates (depending on space conditions, a bi-turbo variant is also possible). The manifold must then be adapted and stapled in conjunction with the turbocharger. If you do not have the possibility to produce the manifold yourself or to have it produced, we are happy to help you.

Stainless steel pipe bends and yard ware for manifold construction 36, 42, 48mm or special dimensions are available from us.

More information about manifolds can be found here in the Turbo manifold FAQ

Turbocharger

The turbocharger, also an important, if not the most important component in a turbo circuit, actually does nothing else but supply the engine with more oxygen in order to obtain more power from an engine by burning a correspondingly larger quantity of fuel.

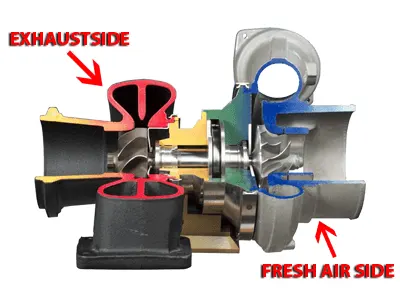

A turbocharger consists of an exhaust gas turbine in the exhaust gas flow (visible in the red area of the turbocharger cross-section), which is connected via a shaft to a compressor in the intake tract. The turbine is driven by the exhaust gas flow of the engine and thus causes the compressor to rotate. The compressor thereby increases the pressure in the engine's intake tract in such a way that a larger amount of air enters the cylinder during the intake stroke than in a naturally aspirated engine. Due to the larger gas volume, Otto turbo engines usually require a reduction of the compression ratio compared to comparable naturally aspirated engines, as otherwise the uncontrolled ignition of the fuel-air mixture (knocking) can occur due to excessive pressures and the resulting high temperature.

Depending on what kind of manifold is used for the turbo conversion and with regard to the exhaust gas temperatures between manifold and supercharger, there are differences in turbochargers between superchargers with an internal wastegate, i.e. a "boost pressure control valve", and external wastegate mounted on the manifold. A distinction is also made between turbochargers with slide bearings and those with ball bearings.

Depending on what kind of manifold is used for the turbo conversion and with regard to the exhaust gas temperatures between manifold and supercharger, there are differences in turbochargers between superchargers with an internal wastegate, i.e. a "boost pressure control valve", and external wastegate mounted on the manifold. A distinction is also made between turbochargers with slide bearings and those with ball bearings.

Click here for the detailed Turbocharger FAQ page

Wastegate

The wastegate can either be integrated in the loader or, if the loader does not have a wastegate, it can be mounted on the manifold. The wastegate guides excess exhaust gases at the turbine into the exhaust system. This happens at a value set on the wastegate and thus prevents damage to the shaft of the supercharger or other components by exceeding the boost pressure.

Internal waste gates, i.e. those integrated into the charger, are more susceptible to damage, as their mechanism, which opens the bypass flap and thus directs the excess exhaust gases past the turbine, sits in the hot exhaust gas flow and is thus exposed to high thermal loads. In addition, a waste gate mounted on the manifold reduces the thermal load between manifold and charger.

Intercooler

To establish the turbo circuit, a connection must be made between the throttle valve and the pressure side of the turbocharger. A charge air cooler is placed between them for cooling down. In addition, a divert-air valve or "blow-off" must be inserted into the charge-air piping. When the blow-off valve is closed, the excess pressure is fed back into the intake tract of the turbocharger; when the valves are open, it is simply released into the atmosphere.

More information is available here: Intercooler FAQ

Air filter/ Air intakes

On naturally aspirated engines the air filter is in the intake line. However, as the turbocharged engine sucks in the charger, the air filter must be connected to the intake side of the charger with a suitable pipe (if necessary with the air flow meter, if there was one before). The connection of the individual components and their piping is best done with pressure and heat resistant, multi-layer silicone hoses.

Get more information about air intake systems here in the Air intake systems FAQ

Blow Off Valve / Diverter valve

An SUV (diverter valve) generally has the task of diverting the compressed air that is produced while driving. Thus the turbocharger is not braked. A so-called turbo lag (the time in which the ram pressure cannot escape) is thus prevented.

You can find more information about this in the Diverter Valve FAQ

Downpipe & Exhaust technology

As a component of the exhaust system, the Y-pipe or also called flame pipe or downpipe is the link between the charger and the rest of the exhaust system. The Y-pipe contains two lambda sensor nuts, one for the lambda sensor for general operation and a second nut for the lambda sensor for measuring the value during tuning. This is closed with a screw after successful tuning. There is a rule of thumb for the rest of the exhaust system: The larger the diameter of the Y-pipe and the rest of the exhaust system, the better the exhaust pressure can escape and the charger can rotate more freely.

More information about downpipes can be found here in the Downpipe FAQ

Exhaust Systems

Exhaust system, also known as "exhaust", is the part of an engine through which the exhaust gases are led to the outside. As a whole, an exhaust system consists of a downpipe and the pipe routing with silencers. Finally, tailpipes are usually added.

More information on exhaust systems in general and on Bull-X and EGO-X systems can be found here in the Exhaust systems FAQ

Fuel supply

Power comes from fuel. Turbo engines produce a larger volume of air at full load than naturally aspirated engines. A vehicle that runs too lean (i.e. with too little fuel) risks engine damage. Therefore a lambda test must be carried out and if necessary the values must be adjusted by means of larger injection valves, increased fuel pressure with a fuel pressure regulator or software adaptation in accordance with the ignition angle. For extremely performance-enhancing conversions, a stronger or additional fuel pump may be required.

Compaction reduction

To drive a higher mixture from a boost pressure of 0.4 bar, the compression must be reduced. This can be done either by a compression reduction plate in combination with 2 original head gaskets or alternatively with forged pistons with the correct compression ratio.

Approval / German MOT

In order to be able to move legally on the streets, you need an expert opinion for many tuning parts, which allows the further driving. Here one differentiates between EWG (former ABE) and part certificates.

More information about this topic you will get HERE

Silicone Hoses

Silicone Hoses Silicone hoses and hose kits from SF Hoses offer the perfect solution for replacing original hoses in car, motorcycle, truck, boat or general internal combustion engine applications.

More information about silicone hoses can be found HERE