Turbochargers are not equal at all. So we´ll tell you the difference between slide and ball bearing, with internal wastegate or external wastegate, as well as the differences between the different fresh and exhaust gas sides.

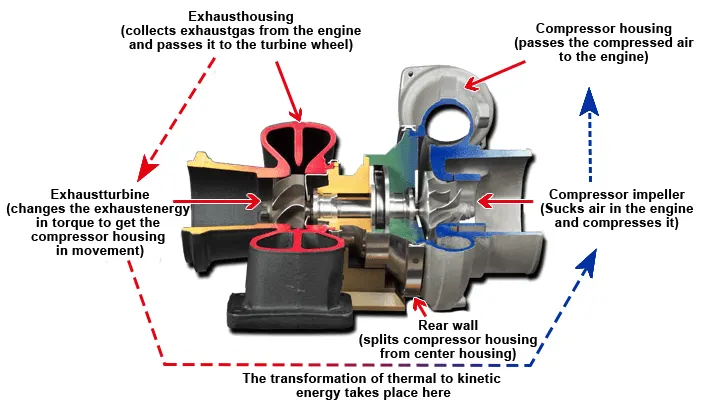

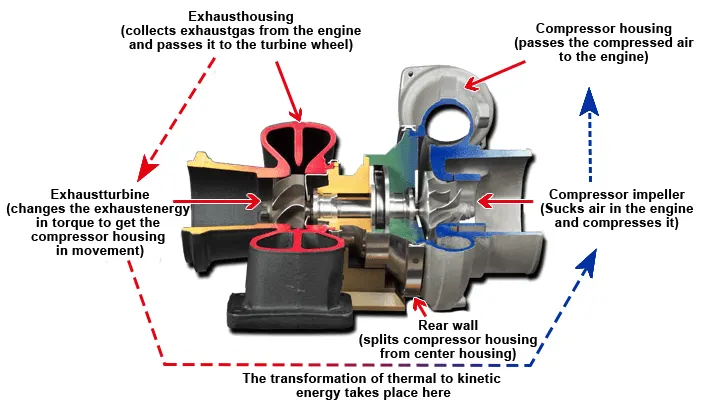

A turbocharger is simply said an energy changer. It converts thermal energy (the engine´s hot exhaust gases, which otherwise leave the system unused) into kinetic energy (the driving of the compressor wheel). The compressor wheel has the important roll to absorb the fresh air with the shovel and compress it at the same time. Because of that the engine gets more fresh air. More oxygen air means a better combustion, but that also significates, that there is more fuel needed, otherwise the engine would work less. But before dealing with the issue of the fresh air flow of a turbocharger and the decision which loader it should be, deal with the component that drives the compressor wheel, and thus has a say when it comes to how fast a turbocharger absorbs – the turbine shaft.

Because this can be stored as follows:

ball bearing

A ball bearing turbocharger has a shaft inside the bearing bush. When the oil supply is running, an oil film forms between the bushing and the shaft, which makes the shaft smoother. A ball bearing charger has the advantage that it can be revisable, because the mechanic dispenses a complicated ball bearing. This means that it could be repaired in case of a shaft or bearing damage. Another advantage that should be mentioned is that it can be perceived as pleasant for some car owners to build a homogeneous performance field, the performance doesn´t come immediately.

The „unreasonable opposite“ to the ball-bearing turbocharger is the

ball mounted

turbocharger. It can NOT be revised in the event of damage to the shaft or bearings ... however, it can have the advantages of being able to quickly build up high pressure even with small amounts of exhaust gas. Especially recommended for small engines or for those drivers who want to feel the power abruptly, since he needs less time to get up to speed and therefore more fresh air can promote and compact. In addition, a ball mounted loader allows a turbo lag less, as it builds up the boost pressure faster even after load changes.

But when does a customer know which size the turbocharger, or the fresh air and exhaust side needs to have. For that you should know that the exhaust and fresh air side have different sizes with specific volume. Starting at the exhaust side, this volume must first be completely filled with exhaust gases until the loader unfolds its full power. This means that if you choose a charger with a too large exhaust side for a small engine, the engine will fill the exhaust side too slow and the response decreases or doesn´t arise at all.

On the other side, if you choose a too small exhaust side, the temperature in the exhaust side gets too high, the exhaust side gets cracked and leaking. In the worst case the charger can be destroyed totally. Additionally, the excessive amount of exhaust gases results in an exhaust backpressure that increases the temperature and leads to thermal problems. Even if the charger doesn´t get any damages under the excessive amount of exhaust gases, it will at least „overdrive“ at high engine speeds and won´t build up any power at all.

The behaviour on the fresh air side is a bit different. A larger side and accordingly a bigger compressor impeller make sense because a compressor impeller boosts a bigger fresh air side and higher volume flow even in lower engine speed. But there the problem begins... the bigger the compressor impeller, he more mass and inertia it has on and thus takes more time again to turn up. Besides that, it would promote a fresh air volume which is too big, so the engine would have a volume of gas-air mixture, that the engine couldn´t work with.

Before we get to the last difference, a turbocharger with internal or external wastegate we summarize by an example:

We have a small engine with an engine capacity of 1,6L and want to have a better response and sudden power delivery after the turbo modification, because we want to use the conversion more in city traffic or on short-distance sprints. In this case it would be better to use a ball mounted turbocharger with a small exhaust and a bigger fresh air side. Because of that we have a charger which is ready even with low exhaust volume and can unfold its power by the ball mounting. It´s okay if the power isn´t unfold at higher engine speed because we mostly want to use it on short sprints.

Now another example: We have an engine with big capacity and want to have a harmoniously build up power development, because a sudden power delivery wouldn´t make any sense here. Additionally, we would like to have a power reserve in the upper engine speed because we want to call it up on long distance drives. So we choose a ball bearing turbocharger with a big exhaust side and a similar or a bit bigger fresh air side. Through the ball bearing we still have a power reserve in the upper engine capacity and through the bigger fresh air side we have bigger volume which can be supported. We can tolerate the lazy response because we don´t care about speed ups on short distance areas.

We hope that these examples and the previous explanations could help you already, as we now address the final difference that would be there: Turbocharger with internal or external wastegate?

Whether internal or external, the wastegate transfers unnecessary exhaust gases to the turbine of the turbocharger to the exhaust system. This happens in a value set at the wastegate to prevent damage to the shaft of the charger or other components by exceeding the boost pressure. Internal wastegates, which are integrated in the loader, are more susceptible to damage, as their mechanism, which opens the bypass flap and thus bypasses the superfluous exhaust gases on the turbine, sits in the hot exhaust gas flow and is thus exposed to high thermal loads. Furthermore, a wastegate mounted on the manifold reduces the load due to thermal effects between the manifold and the turbocharger, because the unnecessary hot exhaust gases already escape in the manifold and not in the turbocharger.

Turbochargers are not equal at all. So we´ll tell you the difference between slide and ball bearing, with internal wastegate or external wastegate, as well as the differences between the...

read more » Close window Turbocharger FAQ

Turbochargers are not equal at all. So we´ll tell you the difference between slide and ball bearing, with internal wastegate or external wastegate, as well as the differences between the different fresh and exhaust gas sides.

A turbocharger is simply said an energy changer. It converts thermal energy (the engine´s hot exhaust gases, which otherwise leave the system unused) into kinetic energy (the driving of the compressor wheel). The compressor wheel has the important roll to absorb the fresh air with the shovel and compress it at the same time. Because of that the engine gets more fresh air. More oxygen air means a better combustion, but that also significates, that there is more fuel needed, otherwise the engine would work less. But before dealing with the issue of the fresh air flow of a turbocharger and the decision which loader it should be, deal with the component that drives the compressor wheel, and thus has a say when it comes to how fast a turbocharger absorbs – the turbine shaft.

Because this can be stored as follows:

ball bearing

A ball bearing turbocharger has a shaft inside the bearing bush. When the oil supply is running, an oil film forms between the bushing and the shaft, which makes the shaft smoother. A ball bearing charger has the advantage that it can be revisable, because the mechanic dispenses a complicated ball bearing. This means that it could be repaired in case of a shaft or bearing damage. Another advantage that should be mentioned is that it can be perceived as pleasant for some car owners to build a homogeneous performance field, the performance doesn´t come immediately.

The „unreasonable opposite“ to the ball-bearing turbocharger is the

ball mounted

turbocharger. It can NOT be revised in the event of damage to the shaft or bearings ... however, it can have the advantages of being able to quickly build up high pressure even with small amounts of exhaust gas. Especially recommended for small engines or for those drivers who want to feel the power abruptly, since he needs less time to get up to speed and therefore more fresh air can promote and compact. In addition, a ball mounted loader allows a turbo lag less, as it builds up the boost pressure faster even after load changes.

But when does a customer know which size the turbocharger, or the fresh air and exhaust side needs to have. For that you should know that the exhaust and fresh air side have different sizes with specific volume. Starting at the exhaust side, this volume must first be completely filled with exhaust gases until the loader unfolds its full power. This means that if you choose a charger with a too large exhaust side for a small engine, the engine will fill the exhaust side too slow and the response decreases or doesn´t arise at all.

On the other side, if you choose a too small exhaust side, the temperature in the exhaust side gets too high, the exhaust side gets cracked and leaking. In the worst case the charger can be destroyed totally. Additionally, the excessive amount of exhaust gases results in an exhaust backpressure that increases the temperature and leads to thermal problems. Even if the charger doesn´t get any damages under the excessive amount of exhaust gases, it will at least „overdrive“ at high engine speeds and won´t build up any power at all.

The behaviour on the fresh air side is a bit different. A larger side and accordingly a bigger compressor impeller make sense because a compressor impeller boosts a bigger fresh air side and higher volume flow even in lower engine speed. But there the problem begins... the bigger the compressor impeller, he more mass and inertia it has on and thus takes more time again to turn up. Besides that, it would promote a fresh air volume which is too big, so the engine would have a volume of gas-air mixture, that the engine couldn´t work with.

Before we get to the last difference, a turbocharger with internal or external wastegate we summarize by an example:

We have a small engine with an engine capacity of 1,6L and want to have a better response and sudden power delivery after the turbo modification, because we want to use the conversion more in city traffic or on short-distance sprints. In this case it would be better to use a ball mounted turbocharger with a small exhaust and a bigger fresh air side. Because of that we have a charger which is ready even with low exhaust volume and can unfold its power by the ball mounting. It´s okay if the power isn´t unfold at higher engine speed because we mostly want to use it on short sprints.

Now another example: We have an engine with big capacity and want to have a harmoniously build up power development, because a sudden power delivery wouldn´t make any sense here. Additionally, we would like to have a power reserve in the upper engine speed because we want to call it up on long distance drives. So we choose a ball bearing turbocharger with a big exhaust side and a similar or a bit bigger fresh air side. Through the ball bearing we still have a power reserve in the upper engine capacity and through the bigger fresh air side we have bigger volume which can be supported. We can tolerate the lazy response because we don´t care about speed ups on short distance areas.

We hope that these examples and the previous explanations could help you already, as we now address the final difference that would be there: Turbocharger with internal or external wastegate?

Whether internal or external, the wastegate transfers unnecessary exhaust gases to the turbine of the turbocharger to the exhaust system. This happens in a value set at the wastegate to prevent damage to the shaft of the charger or other components by exceeding the boost pressure. Internal wastegates, which are integrated in the loader, are more susceptible to damage, as their mechanism, which opens the bypass flap and thus bypasses the superfluous exhaust gases on the turbine, sits in the hot exhaust gas flow and is thus exposed to high thermal loads. Furthermore, a wastegate mounted on the manifold reduces the load due to thermal effects between the manifold and the turbocharger, because the unnecessary hot exhaust gases already escape in the manifold and not in the turbocharger.