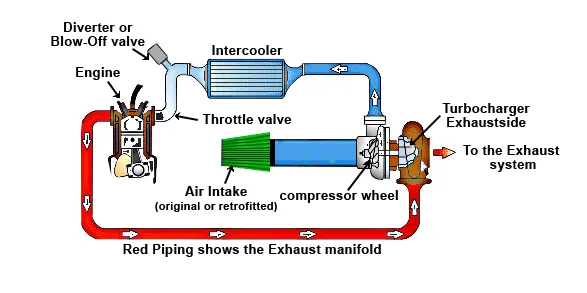

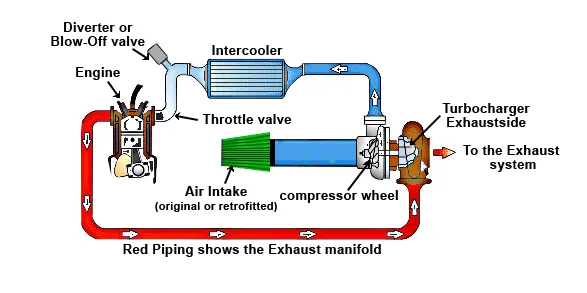

An intercooler is a component in the boost air system of charged cars, whether turbo-, compressor- or G-charged. The intercooler lowers the stream of air from the wind and the heat of the flowing charge air. Because the air supplied to the engine is cooler, the car can achieve higher performance. The size of the intercooler depends on the performance of the car and the volume of the needed charged air.

When it comes to the piping between turbocharger, intercooler and throttle plate, you need to think about that every turbocharger has only a limited output of fresh air, which it can compress. Because of that, bigger piping makes no sense if the volume of the cold charge air is so big, that the turbocharger can´t use all of it. In addition, the charger needs more time to fill the charge air pipes with cold and compressed air, the bigger the diameter is. And the responsiveness of the car gets worse, too.

In summary, it can be said that in the charge air piping (regardless of whether turbo retrofit or standard turbo vehicles where you want to obstruct a front-side intercooler), make sure that the cross section of the pipes and thus the volume to be filled by the loader is not too large, or unnecessarily long paths are gone with the charge air piping, which also increases the volume.

In addition to the assembly, there are silicone hoses and clamps, and of course intercooler in a variety of sizes and complete, ready-made kits with vehicle-specific charge air pipes.

Of course, we can offer individual charge air piping or intercooler inhouse, just like you need it for your car. If you don´t have the possibility to weld aluminium, just send us the marked pipes, you adapted on your car before. And then we can weld the aluminium in TIG- welding process for you.

Watercooler

Therefore two coolers are needed. The first is surrounded by water and cools down the charge air. And then a second watercooler, which is front installed. For the water circulation there is an electrical pump needed. A decisive argument against a watercooler is, that it can freeze in winter. Because of that we only offer intercoolers that work with inhaled air.

Back pressure

Backpressure at intercooler comes when the air accumulates and doesn´t move forwards. This can happen for example if the core is built to narrow or even if it´s clogged (dirt).

Responsiveness

The responsiveness equals a time course when and how power is available. This is known when it comes to the performance of, for example, turbocharger and engine. The better the responsiveness is, the faster the component performance is available.

At the turbocharger the responsiveness describes the acceleration behaviour from the charger. The better the responsiveness is, the faster the charger gets loaded. Mostly smaller turbocharger has a better responsiveness as bigger ones, because there is less exhaust gases or rather energy is needed to get the compressor in rotation.

The optimization of the response can be achieved by targeting the improvement of the periphery. This includes intakes systems, Turbooutlets and so on.

An intercooler is a component in the boost air system of charged cars, whether turbo-, compressor- or G-charged. The intercooler lowers the stream of air from the wind and the heat of the flowing...

read more » Close window Intercooler FAQ

An intercooler is a component in the boost air system of charged cars, whether turbo-, compressor- or G-charged. The intercooler lowers the stream of air from the wind and the heat of the flowing charge air. Because the air supplied to the engine is cooler, the car can achieve higher performance. The size of the intercooler depends on the performance of the car and the volume of the needed charged air.

When it comes to the piping between turbocharger, intercooler and throttle plate, you need to think about that every turbocharger has only a limited output of fresh air, which it can compress. Because of that, bigger piping makes no sense if the volume of the cold charge air is so big, that the turbocharger can´t use all of it. In addition, the charger needs more time to fill the charge air pipes with cold and compressed air, the bigger the diameter is. And the responsiveness of the car gets worse, too.

In summary, it can be said that in the charge air piping (regardless of whether turbo retrofit or standard turbo vehicles where you want to obstruct a front-side intercooler), make sure that the cross section of the pipes and thus the volume to be filled by the loader is not too large, or unnecessarily long paths are gone with the charge air piping, which also increases the volume.

In addition to the assembly, there are silicone hoses and clamps, and of course intercooler in a variety of sizes and complete, ready-made kits with vehicle-specific charge air pipes.

Of course, we can offer individual charge air piping or intercooler inhouse, just like you need it for your car. If you don´t have the possibility to weld aluminium, just send us the marked pipes, you adapted on your car before. And then we can weld the aluminium in TIG- welding process for you.

Watercooler

Therefore two coolers are needed. The first is surrounded by water and cools down the charge air. And then a second watercooler, which is front installed. For the water circulation there is an electrical pump needed. A decisive argument against a watercooler is, that it can freeze in winter. Because of that we only offer intercoolers that work with inhaled air.

Back pressure

Backpressure at intercooler comes when the air accumulates and doesn´t move forwards. This can happen for example if the core is built to narrow or even if it´s clogged (dirt).

Responsiveness

The responsiveness equals a time course when and how power is available. This is known when it comes to the performance of, for example, turbocharger and engine. The better the responsiveness is, the faster the component performance is available.

At the turbocharger the responsiveness describes the acceleration behaviour from the charger. The better the responsiveness is, the faster the charger gets loaded. Mostly smaller turbocharger has a better responsiveness as bigger ones, because there is less exhaust gases or rather energy is needed to get the compressor in rotation.

The optimization of the response can be achieved by targeting the improvement of the periphery. This includes intakes systems, Turbooutlets and so on.