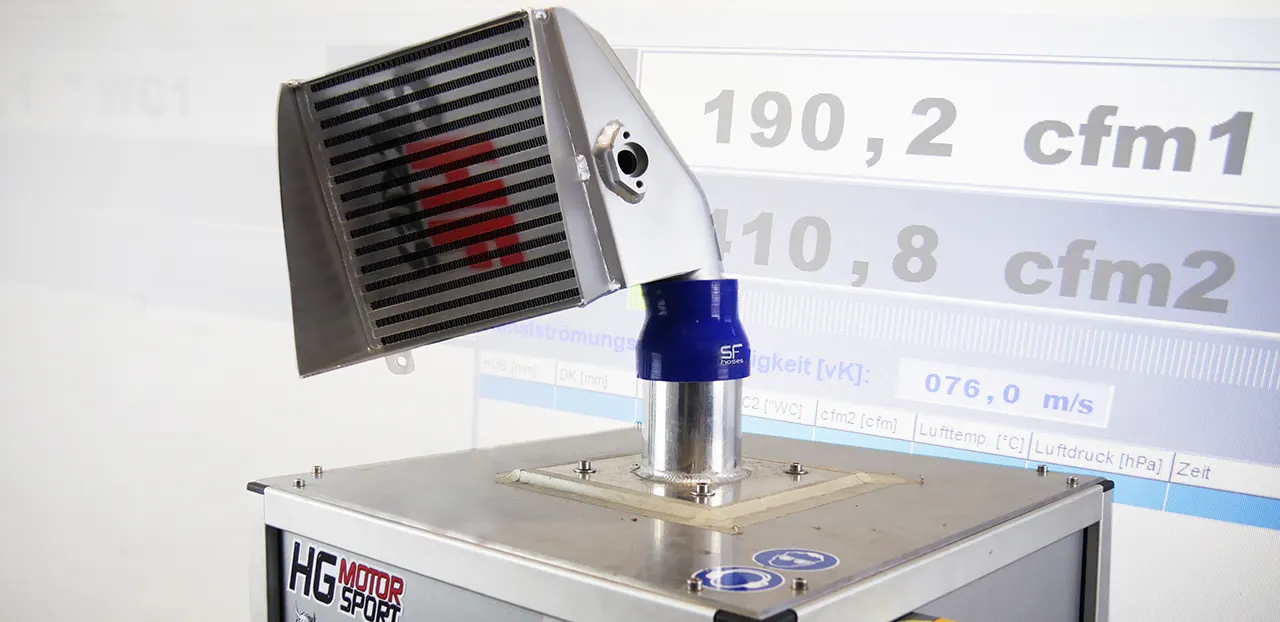

In order to be able to present the measurement conditions and flow behaviour of prototypes as realistically as possible, we use on quite all products and new development a so called Flowbench measurement.

A Flowbench is a measuring device which can perform the measurement of the flow behavior of a component with high precision and speed.

A Flowbench consists of an air pump, a dosing element, pressure and temperature measuring devices such as a manometer and various controls.

In order to be able to test the component to be tested on the Flowbench, the component with the pump and the measuring element is mounted in series and air is sucked through the entire system.

Since the size of the volume flow through the metering element is known, the mass flow rate can be calculated using the known pressure and temperature data and multiplied by the volume flow rate.

The results obtained provide information on structural changes of a prototype and the effect on the flow development within this component.

For our Flowbench measurements we use the FI-3000S from Flowimprover from Germany.

In order to be able to present the measurement conditions and flow behaviour of prototypes as realistically as possible, we use on quite all products and new development a so called...

read more » Close window Flowbench FAQ

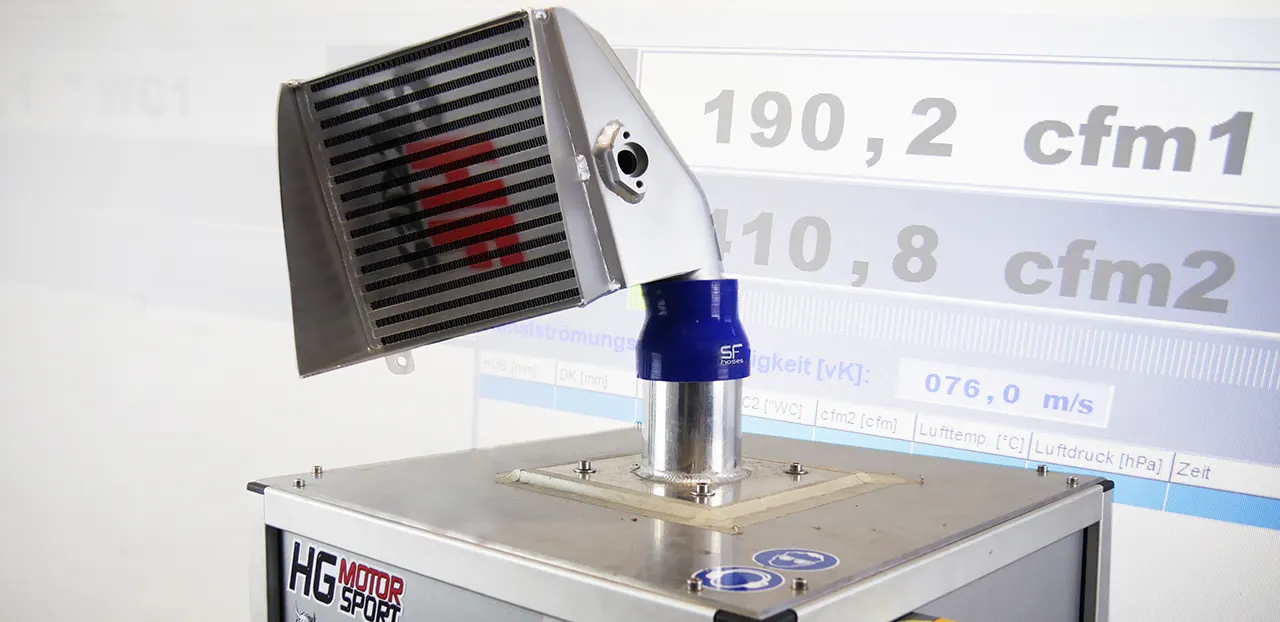

In order to be able to present the measurement conditions and flow behaviour of prototypes as realistically as possible, we use on quite all products and new development a so called Flowbench measurement.

A Flowbench is a measuring device which can perform the measurement of the flow behavior of a component with high precision and speed.

A Flowbench consists of an air pump, a dosing element, pressure and temperature measuring devices such as a manometer and various controls.

In order to be able to test the component to be tested on the Flowbench, the component with the pump and the measuring element is mounted in series and air is sucked through the entire system.

Since the size of the volume flow through the metering element is known, the mass flow rate can be calculated using the known pressure and temperature data and multiplied by the volume flow rate.

The results obtained provide information on structural changes of a prototype and the effect on the flow development within this component.

For our Flowbench measurements we use the FI-3000S from Flowimprover from Germany.