Downpipe & Precat FAQ

DOWNPIPES

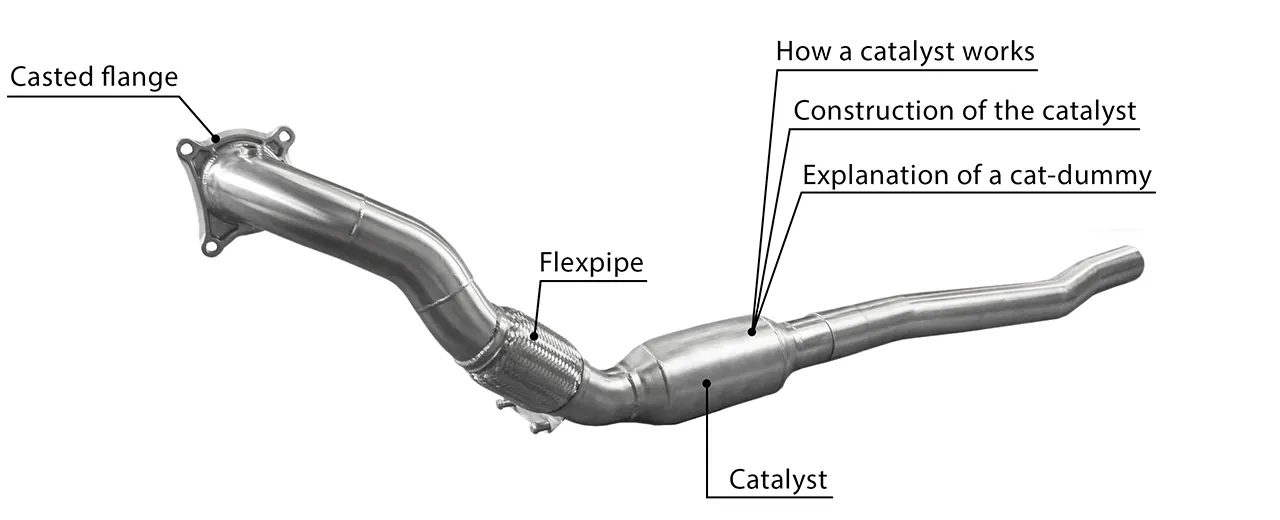

OEM downpipes are mounted between the turbocharger and the exhaust system in turbocharged vehicles. If lower exhaust temperatures and higher torque are required, downpipes should be built with two pipes. The lambda sensor is often located at the beginning of the OEM downpipe. An additional connection for a broadband lambda sensor (to measure the lambda values for software adjustment) is usually placed in front of the catalytic converter, as this falsifies the ratio of the air/petrol mixture. The transition to the next component, the sports catalytic converter, is made via a flexible connection. This connecting link is called a flexpipe. The flexpipe is used to decouple the vibrations and rolling movements of the engine from the exhaust system mounted on the underbody.

OEM downpipes are mounted between the turbocharger and the exhaust system in turbocharged vehicles. If lower exhaust temperatures and higher torque are required, downpipes should be built with two pipes. The lambda sensor is often located at the beginning of the OEM downpipe. An additional connection for a broadband lambda sensor (to measure the lambda values for software adjustment) is usually placed in front of the catalytic converter, as this falsifies the ratio of the air/petrol mixture. The transition to the next component, the sports catalytic converter, is made via a flexible connection. This connecting link is called a flexpipe. The flexpipe is used to decouple the vibrations and rolling movements of the engine from the exhaust system mounted on the underbody.

The same rule applies to the diameter of the OEM downpipes or precatalyst replacement pipes as to the rest of the exhaust system: the larger the diameter, the better and faster the exhaust pressure can escape and the turbocharger can turn up more freely, which has a positive effect on the response behaviour. In addition, the exhaust gas temperature load on the components is reduced.

The so-called precatalyst replacement pipe has a similar effect. This is mounted on the charger like the OEM downpipe and replaces the installed precatalyst in newer vehicles due to today's exhaust gas regulations. By the construction of the precatalyst the exhaust gases are slowed down and an exhaust back pressure is created.

This again has a negative effect on the response behaviour and acceleration, as the turbocharger has to work against the exhaust backpressure.

To avoid this, the precatalyst replacement pipe is mounted instead of the precatalyst and the rest of the exhaust system is flanged to the end of the pipe.

If you would like to make a Y-pipe or a Vorkat replacement pipe yourself, please contact us if you are still looking for the appropriate flanges. We would be pleased to have them produced for you (also as individual production).

WHAT IS A CATALYST?

The honeycomb bodies of the catalytic converters, which are made of ceramic or metal, serve to increase the surface area over which the exhaust gas flows as much as possible in order to ensure the best possible course of the reaction.

The honeycomb bodies of the catalytic converters, which are made of ceramic or metal, serve to increase the surface area over which the exhaust gas flows as much as possible in order to ensure the best possible course of the reaction.

If you would like to replace your original catalytic converter with a sport or tuning catalytic converter, the following should be considered in advance to ensure optimum functioning:

The choice of a suitable sports catalyst should generally be made in accordance with the engine capacity, the performance and the exhaust emission standard.

Furthermore, it is recommended to install the sports catalytic converter, as well as the lambda sensors, always in their original positions to ensure the efficiency of the catalytic converter, as it needs a certain temperature during cold run/cold start to work correctly.

WHAT IS A CATALYST-DUMMY?

A dummy cat is a catalyst housing which is empty, i.e. it does not have a honeycomb body and the corresponding coating and its properties.

A dummy cat is only meant to give the impression that a catalyst is present.

Due to the lack of conversion of the pollutants, especially in newer vehicles, errors in the engine electronics can occur, since the lambda sensors produce incorrect values.

In addition, the installation of a dummy cat represents an attempt at tax evasion if the vehicle is moved on public roads, as the vehicle tax relates to the actual exhaust emission standard of your vehicle. If your emission standard deteriorates because you do not have a catalytic converter, you would theoretically have to pay more vehicle tax.

Dummy catalytic converters are generally not permitted in the STVZO area.

You can find more information about sports catalysts here: Sportcatalyst FAQ

FLEXPIPE

A flexpipe is a flexible part of a downpipe, which are generally made of stainless steel at HG-Motorsport, and thus promises the highest lifetime for your downpipe. The wire mesh pipe is designed to absorb the vibrations coming from the engine, so that the remaining part of the exhaust system is relieved. Furthermore, it also prevents the transmission of noise to the interior, which leads to an improved driving comfort.

A flexpipe is a flexible part of a downpipe, which are generally made of stainless steel at HG-Motorsport, and thus promises the highest lifetime for your downpipe. The wire mesh pipe is designed to absorb the vibrations coming from the engine, so that the remaining part of the exhaust system is relieved. Furthermore, it also prevents the transmission of noise to the interior, which leads to an improved driving comfort.

INTERLOCK

In the area of a flexible tube, interlock means the interlocking of several stainless steel rings that are as flexible as the outside of the flexible tube. Thus it is more resilient and the wear of the flexible tube is also kept lower.

In the area of a flexible tube, interlock means the interlocking of several stainless steel rings that are as flexible as the outside of the flexible tube. Thus it is more resilient and the wear of the flexible tube is also kept lower.

CAST FLANGE

A cast flange is manufactured from only one single part. Hence the name, because it is cast in a sample template and is therefore always identical. This optimizes the flow because there are no butt edges at the inlet of the downpipe. With Bull-X down pipes, the cast flange is always made of stainless steel to create an increased durability.

EXHAUST SYSTEMS & DOWNPIPE SPECIAL CONSTRUCTION ACCORDING TO CUSTOMER REQUIREMENTS

Just as with the special production of intake, pressure and charge air pipes, you also have the possibility to have downpipes and exhaust systems manufactured according to your wishes. For this purpose we will send you the raw material, if you need it. You cut the pipes to length, mark the positions of the pipe segments in relation to each other with lines, name the respective component at the end (three-hole flange, V-band clamps etc.) and we weld your workpiece for you using the high-quality TIG welding process! This gives you all-round quality and durability, even if you want to carry out your conversion in your own garage.

Just as with the special production of intake, pressure and charge air pipes, you also have the possibility to have downpipes and exhaust systems manufactured according to your wishes. For this purpose we will send you the raw material, if you need it. You cut the pipes to length, mark the positions of the pipe segments in relation to each other with lines, name the respective component at the end (three-hole flange, V-band clamps etc.) and we weld your workpiece for you using the high-quality TIG welding process! This gives you all-round quality and durability, even if you want to carry out your conversion in your own garage.